Installation Tolerances vs. Air Leakage: What North Texas Homeowners Need to Know

When it comes to replacing windows in North Texas homes, many homeowners are unaware that installation quality is just as important as the window itself. Even high-performance windows can underperform if gaps and misalignments occur during installation. This is especially true for homes built 20–35 years ago, which often feature builder-grade aluminum windows prone to air leakage, drafts, and energy loss.

Here’s why this matters:

- Texas heat and shifting foundations can worsen small gaps around windows, leading to higher energy bills and uncomfortable indoor temperatures.

- Air leakage isn’t just about the window assembly – it often happens around the frame due to poor sealing or improper shimming.

- FGIA-certified installation ensures precise tolerances, reducing drafts, improving energy efficiency, and keeping your home comfortable year-round.

If your home still has aging builder-grade windows, upgrading to modern, energy-efficient options with proper installation can make a noticeable difference in comfort, noise reduction, and utility costs. Let’s explore how air leakage happens, why installation tolerances matter, and how certified methods can transform your home.

How to Air Seal and Install Windows for Lasting Durability

What Are Installation Tolerances?

When it comes to energy efficiency, precise installation tolerances are crucial for getting the most out of your windows. These tolerances refer to the allowable gaps and clearances between the window frame and the rough opening. They ensure the frame is plumb, level, and square while maintaining proper spacing at the jambs (sides), sill (bottom), and head (top). This precision is what allows for a tight seal, keeping your home comfortable and energy-efficient.

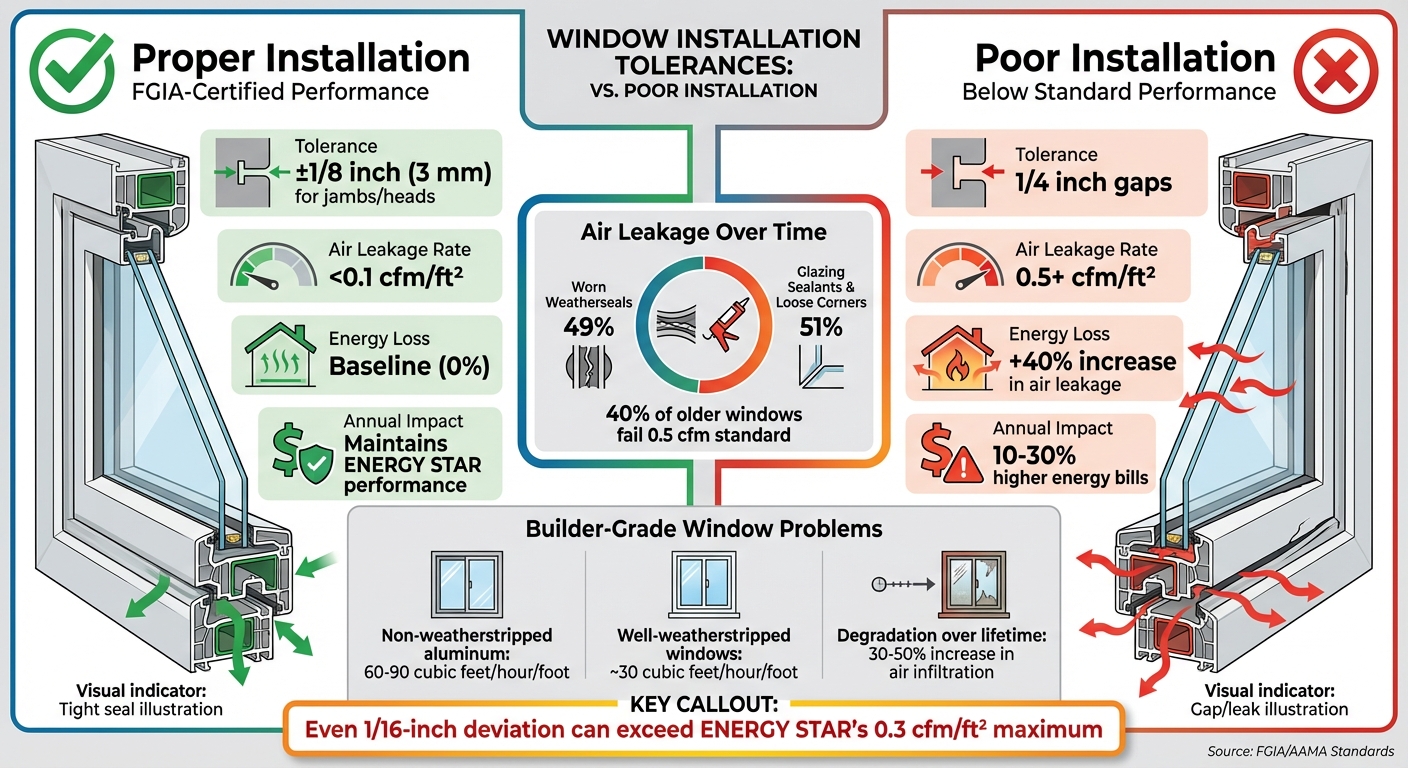

For FGIA-certified installations, these tolerances are extremely tight – typically within ±1/8 inch (3 mm) for jambs and heads, and between 1/16 and 1/8 inch (1.5–3 mm) for sill depth variations. Even these small differences can determine whether a window seals properly or allows air leaks. As the Building Science Corporation puts it:

“Window work requires tight tolerances and is workmanship sensitive; significant air leakage can result if tolerances are too loose”.

FGIA and AAMA Standards

The FGIA (formerly AAMA) sets strict guidelines for installation tolerances to ensure windows perform as intended. For jambs and heads, gaps shouldn’t exceed 1/8 inch before shimming and sealing. If these gaps increase to 1/4 inch, air leakage can rise by 40%, jumping from 0.3 CFM/ft² to 0.5 CFM/ft² or more. At the sill, tolerances are even tighter – depth variations must stay within 1/8 inch, and any gap over 1/4 inch requires shimming to maintain proper drainage and prevent infiltration. For the head, gaps should remain under 3/8 inch to ensure weatherseals compress effectively, even as materials expand and contract with temperature changes.

These numbers aren’t random. Studies on windows aged 2 to 43 years show that 49% of long-term air leakage stems from worn weatherseals – often due to poor head tolerances. The remaining 51% comes from issues like glazing sealants and loose corner joints.

Why Precision Matters in Installation

Precision in installation isn’t just about meeting guidelines – it’s about ensuring your home stays comfortable, efficient, and protected. When jambs, sills, and heads are installed within ±1/8 inch tolerances, weatherseals work as intended, keeping air leakage below 0.3 CFM/ft². On the flip side, even a 1/4 inch deviation can lead to thermal bridging and moisture intrusion, accelerating window wear by up to 40% over 20 years.

In North Texas, where summer temperatures regularly soar above 100°F, small gaps can quickly become big problems. Hot air, dust, and noise seep in, while energy bills climb 10–30% higher than they should be.

At Optimal Windows, installers follow FGIA-certified practices to ensure every window is plumb, level, and properly shimmed. They use tools like levels, plumb bobs, and shims to achieve exact measurements, followed by low-expansion foam and backer rods for gaps under 1 inch, finishing with high-quality caulking. This meticulous approach reduces air leakage by 50–70% compared to non-certified installations, ensuring the lab-tested performance of your windows translates into real-world results. For homeowners in Plano, Frisco, McKinney, and North Dallas, this precision means long-lasting energy efficiency and comfort.

What Is Air Leakage and Why Does It Matter?

Air leakage refers to the unwanted flow of outdoor air into your home through gaps in windows and doors. This issue not only disrupts indoor comfort but also drives up heating and cooling expenses. It can occur in two primary ways: through the window assembly itself (where the sash meets the frame, around weatherstripping, or at joints in the hardware) and along the perimeter where the window frame meets the wall if not properly sealed.

In homes with significant air leakage, HVAC systems are forced to work overtime, which can increase heating and cooling costs by as much as 30%. For homeowners in North Texas, where summer temperatures often climb above 100°F, even small gaps can let in hot air, dust, and humidity. This not only makes your living space less comfortable but can also raise energy bills by 10–30% more than necessary.

But the impact doesn’t stop at higher energy costs. Air leakage also creates drafts and uneven indoor temperatures. Much like the wind-chill effect outdoors, moving air affects how your body perceives heat, making the space feel colder or hotter than it actually is. Additionally, these gaps can allow pollen, pollutants, and even noise to enter, reducing indoor air quality and overall comfort .

How Air Leakage Is Measured

To evaluate air leakage, professionals use ASTM E783, a standard field test for installed windows. This test involves creating a consistent pressure difference across the window assembly (typically 1.57 psf or 75 Pa) to simulate wind pressure. Instruments like anemometers or flow meters then measure how much air passes through cracks, with results expressed in cubic feet per minute per square foot of window area (cfm/ft²) .

The National Fenestration Rating Council (NFRC) certifies air leakage ratings for residential windows. To qualify for ENERGY STAR certification, a window must have an air leakage rating of 0.3 cfm/ft² or lower . Many high-performance windows achieve ratings between 0.1 and 0.2 cfm/ft². However, the NFRC does not differentiate between values below 0.1, as differences at that level are considered insignificant. Interestingly, studies have shown that about 40% of tested windows fail to meet the older standard of 0.5 cfm per linear foot of crack.

Understanding how air leakage is measured is just one piece of the puzzle. To address the problem effectively, it’s crucial to identify its root causes.

Main Causes of Air Leakage

Air leakage typically stems from two main sources. The first is frame-related leakage, which happens within the window assembly itself. This can result from worn-out weatherstripping, failed hardware seals, or degraded glazing sealants. Windows lacking proper weatherstripping can leak up to twice as much air as those with well-maintained seals.

The second source is perimeter leakage, which occurs where the window frame meets the surrounding wall. Poor caulking, flashing failures, or improper shimming can create gaps that allow drafts, even if the window unit itself is designed for low leakage. Field studies have shown that upgrading windows with new seals and applying proper caulking can significantly reduce air leakage. This highlights the importance of quality installation in ensuring optimal window performance .

How Installation Tolerances Affect Air Leakage

The way windows are installed has a direct impact on air leakage. FGIA-certified installation practices aim to minimize deviations, but even small gaps can significantly affect energy performance. For example, a mere 1/16-inch deviation can push air leakage beyond 0.3 cfm/ft² – the maximum rate recommended by ENERGY STAR. This seemingly minor issue can lead to HVAC systems working harder, increasing energy costs by as much as 30% in hot climates due to continuous air exchange . Let’s explore how these installation tolerances translate into measurable energy loss.

Field research has shown that identical window models can perform very differently based on installation quality. A study tracking windows aged 2 to 43 years revealed that air leakage worsens over time, especially when installation isn’t done correctly. Misaligned frames, over-shimming, or uneven fastening can create stress points that lead to small gaps at corners and between sashes. Over the years, these gaps widen as windows endure temperature fluctuations, particularly in hot climates where thermal expansion is more pronounced .

Problems with Builder-Grade Windows

Older builder-grade windows are a prime example of how poor installation tolerances can cause long-term issues. Many homes in in Plano, Frisco, McKinney, Allen, and North Dallas, still have builder-grade aluminum windows that struggle with loose sash fits, weather seals that are no longer effective, and frames warped by years of exposure to heat and UV rays. Field tests have shown that 40% of older windows fail to meet the acceptable air leakage standard of 0.5 cfm per linear foot of crack. Much of this excess leakage comes from deteriorated hardware seals and gaps that have widened over time.

One major issue with builder-grade aluminum windows is the lack of proper weatherstripping. Non-weatherstripped aluminum frames can leak air at rates of 60–90 cubic feet per hour per foot of sash crack under conditions equivalent to a 25 mph wind. By comparison, well-weatherstripped windows average around 30 cubic feet per hour per foot. Many builder-grade units start with minimal weatherstripping, which tends to degrade quickly, leading to a 30–50% increase in air infiltration over the window’s lifespan.

How Small Gaps Lead to Energy Loss

When installation tolerances are off, energy efficiency takes a hit. A detailed study found that 49% of air leakage degradation was caused by failing weather seals, while 51% was due to issues with glazing sealants and corner tightness. If frames shift even slightly out of alignment during installation, seals can lose contact, and corner joints may separate. This can result in a 0.1 cfm/ft² increase in air leakage, which translates to a 10–15% rise in annual energy loss .

The numbers tell the story. Windows with poor tolerances often have air leakage ratings between 0.3 and 0.5 cfm/ft² or higher, compared to less than 0.1 cfm/ft² for tightly installed, high-performance windows. Improper installations can double air leakage over time – from 0.3 to 0.6 cfm per linear foot of crack – while FGIA-compliant installations keep leakage rates below 0.3 cfm/ft². This helps prevent drafts and avoids the 20–30% energy waste commonly seen in aging North Texas homes . Proper installation tolerances are essential for ensuring that windows perform as well in real-world conditions as they do in the lab.

FGIA-Certified Installation Methods That Prevent Air Leakage

When it comes to ensuring your windows perform as promised, FGIA-certified installation practices are a game-changer. These methods go beyond standard approaches to create a continuous barrier against air and water, replicating the performance seen in lab-tested ratings. By using a carefully planned combination of flashing, sealants, and insulation materials, certified installations address every potential weak spot. Unlike builder-grade methods that often rely on caulk alone, these advanced techniques layer multiple seals to keep your home protected. This meticulous approach highlights a critical point: a window’s performance is only as good as the quality of its installation.

Sealing Methods for Draft-Free Performance

The process starts with a pre-formed sill pan, designed to slope outward and integrate seamlessly with the weather-resistant barrier. This step prevents water and air from sneaking in at the base of the window, a particularly vulnerable area. Next, self-adhered flashing is applied to the jambs and head, overlapping in a way that directs moisture and air away from your home. For the gaps around the window, a properly sized backer rod is inserted, followed by a flexible sealant. This creates a durable, two-sided bond that adjusts to movement without cracking.

To insulate the space between the window frame and the rough opening, low-expansion spray foam is carefully applied. This foam fills the cavity without putting pressure on the frame, which could lead to warping or gaps. Over-expansion is avoided because it can distort the window, while under-filling leaves room for air leakage. When applied correctly, this foam can cut air leakage by up to 50% compared to improper fills. After securing the window, installers seal any exposed screw heads, installation holes, and adjuster openings per the manufacturer’s guidelines. This step ensures there are no hidden paths for air or water to infiltrate.

Long-Term Efficiency in North Texas Homes

These certified installation techniques are tailored to withstand the unique challenges of the North Texas climate. With scorching summers, intense UV exposure, and high winds, homes in areas like Plano, Frisco, McKinney, and North Dallas face conditions that can quickly compromise substandard installations. FGIA-certified methods utilize UV-resistant sealants and low-expansion foams that endure these harsh conditions without cracking or losing their seal. Even under winds up to 25 mph – equivalent to 0.30 inches of water column pressure – these materials hold strong.

For homes built 20 to 35 years ago, thermal expansion caused by extreme heat can widen gaps in builder-grade installations, leading to drafts and energy loss. Certified installations address these issues, with homeowners often noticing a significant drop in cooling costs after their windows are upgraded. In fact, these methods help maintain air leakage rates below 0.3 cfm/ft², a dramatic improvement for homes with aging, builder-grade windows. Studies on retrofitted homes have shown that certified sealing – when paired with updated weatherstrips and caulking – can reduce air leakage by nearly 49%.

Conclusion

When it comes to ensuring your windows deliver true energy efficiency and comfort, FGIA-certified installation practices make all the difference. These methods focus on maintaining tight tolerances and sealing every perimeter gap using approved techniques. By ensuring frames are plumb, level, and square with proper shimming and clearances, windows can perform much closer to their lab-tested air leakage ratings, giving you the results you expect.

For homeowners in Plano, Frisco, McKinney, and North Dallas, this level of precision is especially important. The intense heat, high winds, and relentless UV exposure of North Texas summers put any window installation to the test. FGIA-based practices, such as using UV-resistant sealants, low-expansion foam, and layered flashing, are designed to withstand these challenges. The result? Conditioned air stays inside, your HVAC system works less, and you enjoy lower utility bills, fewer drafts, and a quieter, more comfortable home.

The difference is clear when looking at feedback from local homeowners. In 2024–2025, those who upgraded to FGIA-certified installations with Optimal Windows consistently reported measurable benefits. Within just a month, many noticed reduced energy bills and improved indoor comfort. These real-world results highlight the performance gap between standard “remove and replace” installations and those that follow rigorous industry standards.

If your home still has 20–35-year-old builder-grade windows, upgrading to NFRC-rated, low-air-leakage windows paired with FGIA-compliant installation isn’t just a smart choice – it’s essential. Choosing an installer who prioritizes precision ensures your new windows deliver the energy savings, comfort, and long-lasting performance your home deserves.

FAQs

How do installation tolerances affect energy efficiency and window performance?

Proper installation tolerances are essential for your windows to function as they should. These tolerances refer to the precise clearances needed during installation to avoid problems like air leaks, drafts, and wasted energy. If the fit is too loose or too tight, gaps can develop, which may compromise energy efficiency, let in unwanted noise, and even cause the windows to fail prematurely.

Achieving long-term performance requires precise installation that adheres to certified standards. This level of accuracy ensures a secure, dependable fit that enhances energy efficiency and keeps your home comfortable, draft-free, and protected from leaks.

Why choose FGIA-certified window installations for your home?

FGIA-certified window installations adhere to rigorous industry guidelines designed to deliver top-notch quality, energy efficiency, and reliable performance over time. These standards aim to reduce common issues like drafts and air leaks, ensuring your windows are installed to provide optimal comfort and help lower energy costs.

Choosing FGIA-certified installation means your windows are fitted properly, offering long-lasting durability and better resistance to harsh weather and everyday wear. It’s a thoughtful choice that boosts your home’s energy efficiency while adding to its overall value.

How does air leakage affect energy efficiency in North Texas homes?

Air leakage plays a big role in how efficiently your home uses energy. When heated or cooled air escapes and outdoor air sneaks in, your HVAC system has to work overtime. The result? Higher energy bills and a home that may feel less comfortable overall.

In North Texas, where summers can be scorching and temperature swings are common, cutting down on air leakage is especially important. Properly installed windows, fitted with exacting precision, can help seal out drafts and leaks. This not only keeps your indoor spaces comfortable but also helps maintain energy efficiency throughout the year.