What Is Vacuum Insulated Glass?

Vacuum Insulated Glass (VIG) is a cutting-edge window technology designed to significantly improve insulation, reduce energy costs, and enhance indoor comfort, all within a remarkably slim profile. Unlike standard double- or triple-pane windows that rely on gas-filled gaps, VIG uses a near-vacuum layer between panes to dramatically limit heat transfer.

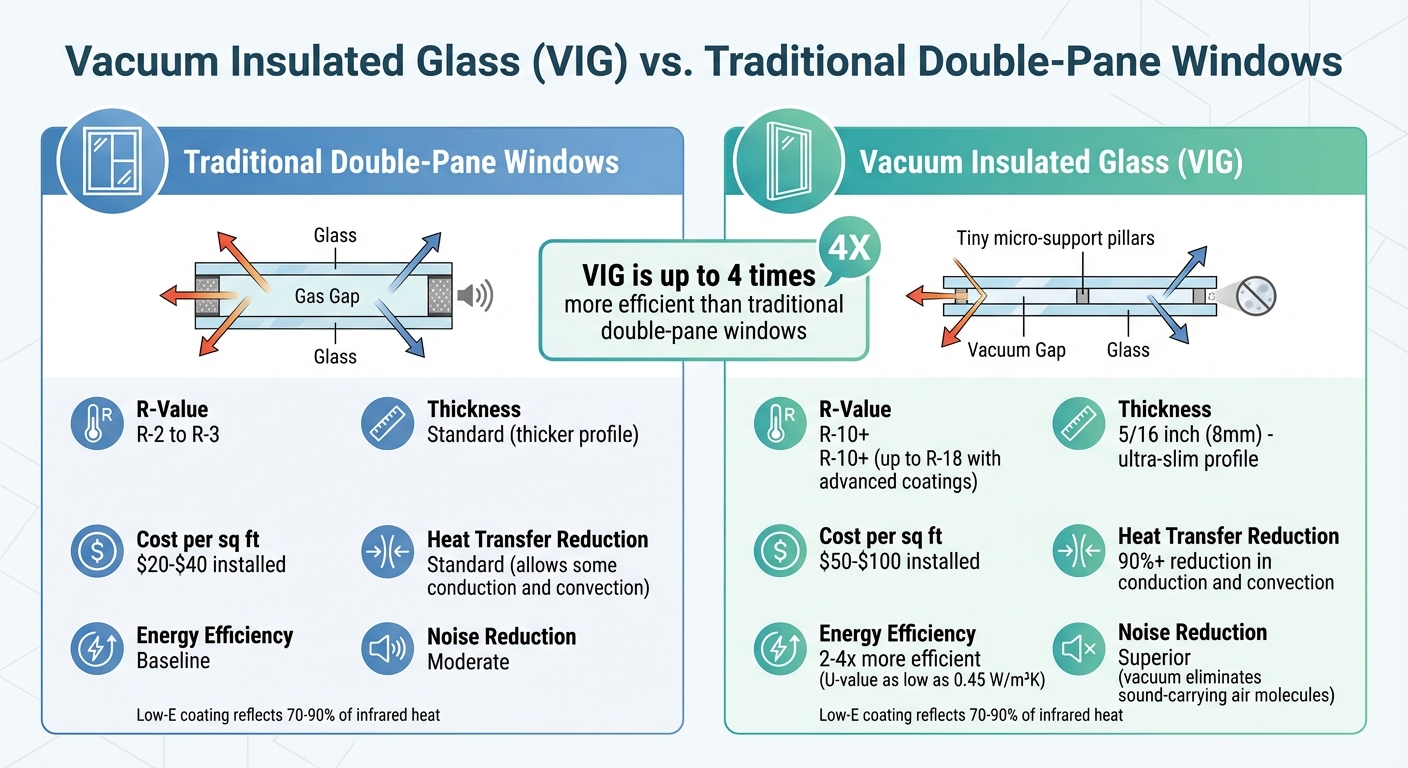

Rather than being “four times more efficient,” VIG delivers approximately 2–4 times under right conditions with insulating performance of standard double-pane windows, depending on glass coatings, frame design, and overall system quality.

In real-world residential applications, high-performance VIG systems typically achieve R-values in the R-5 to R-8 range, placing them among the most efficient glazing options available today.

For homeowners in North Texas, where summers routinely exceed 100°F and winters can bring sharp temperature swings, VIG offers a practical solution to common window problems such as excessive heat gain, drafts, condensation, and high energy bills. VIG also improves sound control, helping create a quieter, more comfortable living environment year-round.

Because VIG operates with much tighter tolerances than traditional insulated glass, proper installation practices such as those outlined in FGIA standards are critical to long-term performance and durability.

If your home still has original builder-grade windows, VIG may be a premium upgrade worth considering to better handle Texas’s extreme climate while improving efficiency and comfort.

“Performance ranges shown reflect best-case system configurations. Actual results vary by product design, coatings, and installation quality.”

How Vacuum Insulated Glass Works

VIG Construction and Components

Vacuum Insulated Glass (VIG) is an advanced glazing system engineered to deliver exceptional insulation in a slim profile. Each VIG unit consists of two panes of glass separated by an ultra-thin vacuum gap, typically 0.2–0.3 mm, roughly the thickness of a human hair.

To prevent the panes from collapsing under atmospheric pressure, tiny coin-shaped micro-support pillars are evenly distributed within the vacuum space. These pillars maintain structural integrity while minimizing heat transfer at each contact point.

The perimeter of the glass is sealed using a hermetic edge seal, commonly made from solder glass or metal, which permanently locks in the vacuum. Many VIG units also include a getter material inside the cavity that absorbs stray gas molecules over time, helping preserve the vacuum and maintain long-term performance.

Despite its advanced construction, the total thickness of a VIG unit is typically around 5/16 inch (approximately 8 mm), comparable to standard double-pane glass but with dramatically higher insulation performance.

How VIG Reduces Heat Transfer

Heat moves through windows in three primary ways, conduction, convection, and radiation. Traditional double-pane windows reduce heat transfer by slowing conduction and convection using insulating gases like argon or krypton, but gas molecules still allow some energy movement.

VIG eliminates nearly all gas molecules by creating a near-vacuum between the panes. This effectively removes convection and significantly reduces conductive heat transfer.

As a result, VIG delivers roughly 2–4 times better thermal performance than standard double-pane windows, often rivaling or outperforming triple-pane systems when thickness and weight are considered.

Some VIG products have demonstrated U-values as low as approximately 0.45 W/m²K in laboratory testing, while real-world residential performance varies based on coatings, frame material, and installation quality.

Rather than matching insulated wall assemblies, VIG dramatically narrows the performance gap between windows and walls, making glazing far less of an energy weak point in the home.

Low-E Coatings and VIG Performance

Beyond eliminating convection and reducing conduction, VIG systems rely on low-emissivity (low-E) coatings to control radiative heat transfer. These microscopic metallic layers are applied to the glass surface facing the vacuum gap and reflect approximately 70–90 percent of infrared heat back toward its source.

In winter, low-E coatings help retain indoor heat. During North Texas summers, they reflect solar heat outward and block most UV radiation, reducing interior heat buildup and protecting furniture and flooring from fading.

When combined with the vacuum layer, low-E coatings significantly enhance real-world VIG performance, pushing insulation well beyond conventional glazing without adding bulk or weight.

Think of VIG like a high-performance thermos. The vacuum acts as the insulating barrier, while the low-E coating functions as the reflective lining that keeps heat where it belongs.

For homeowners in Plano, Frisco, McKinney, and North Dallas, this technology combination helps stabilize indoor temperatures, reduce HVAC strain, and improve year-round comfort when installed correctly.

What Is Vacuum Insulated Glass?

Benefits of Vacuum Insulated Glass

Vacuum insulated glass (VIG) brings a range of practical advantages to homes in North Texas, making it an excellent upgrade for those looking to improve comfort and energy efficiency.

Superior Thermal Insulation

VIG offers a substantial improvement over traditional double-pane windows. While standard dual-pane glass typically performs in the R-2 to R-3 range, residential VIG systems commonly achieve R-5 to R-8.

Rather than matching insulated walls, VIG provides insulation levels far beyond traditional glazing, making windows significantly less of a thermal liability.

This is especially beneficial for large west- or south-facing windows common in North Texas homes, where heat gain often creates hot rooms and uneven comfort.

Reduced Energy Costs

By reducing heat transfer, VIG decreases how often your HVAC system must run. In North Texas, where cooling dominates energy usage for much of the year, this can translate into noticeable reductions in cooling demand and electricity costs.

While VIG carries a higher upfront investment, long-term energy savings, particularly in homes with large glass areas, can help offset that cost over time.

Enhanced Noise Reduction

The vacuum gap inside VIG also improves sound control by eliminating air molecules that normally transmit sound waves.

VIG is most effective at reducing higher-frequency noise such as traffic, voices, and neighborhood activity.

For enhanced sound control, especially against low-frequency noise, VIG performs best when paired with laminated or offset glass configurations.

This makes VIG a strong option for homes near busy streets, schools, or flight paths.

Slim Profile with High Performance

One of VIG’s standout features is its ability to deliver the insulation of triple-pane glass in a slim, lightweight profile similar to double-pane systems. This makes it easier to install than bulkier triple-pane options, which can be a challenge in older homes with frames and sashes not designed to support heavier glass.

The lighter weight and thinner profile also allow for greater design flexibility. VIG works seamlessly with various frame materials – whether vinyl, fiberglass, or composite – without requiring significant structural changes. This means you can enjoy modern, narrow-frame designs that maximize glass area and natural light while still benefiting from top-tier thermal and acoustic performance. For North Texas homeowners, this streamlined profile simplifies FGIA-certified retrofits, ensuring proper installation without the need for extensive frame modifications.

Limitations and Considerations for VIG

While VIG offers impressive performance benefits, its advanced design comes with certain challenges that homeowners should weigh carefully.

Higher Cost and Limited Availability

VIG requires specialized manufacturing, which increases cost compared to standard insulated glass.

Installed pricing typically ranges from $45–$85 or more per square foot, depending on frame material, glass configuration, and installation complexity, roughly two to three times the cost of traditional double-pane windows.

Availability is also more limited, with fewer manufacturers and longer lead times than conventional glass options.

Visible Support Pillars and Installation Requirements

A defining feature of VIG is the use of tiny support pillars that maintain the vacuum between the glass panes. While these pillars are small and minimally noticeable, they do create a subtle grid-like pattern that may slightly disrupt an otherwise clear view.

Additionally, VIG units use a distinct edge seal that differs from those of standard windows. This edge design can impact the sightline and may require adjustments to frame compatibility, particularly in modern window designs that prioritize narrow frames and larger glass areas.

Installing VIG demands precision and expertise. These units are exceptionally thin – typically around 5/16 inch – and more fragile than dual-pane alternatives. This means they must be handled by FGIA-certified professionals trained to work with vacuum-sealed glass. Improper handling or installation can compromise the vacuum seal, leading to performance issues.

In North Texas, where summer temperatures often exceed 100°F, thermal expansion can place additional stress on window seals. Proper frame alignment and expert installation are critical to preventing seal failures in these conditions. Unlike dual-pane windows, which offer some flexibility, VIG requires meticulous care during installation to ensure long-term durability and performance.

Is VIG Right for Your North Texas Home?

Let’s dive into how Vacuum Insulated Glass (VIG) fits into the unique needs of North Texas homes. From battling intense sunlight to minimizing noise, VIG offers a range of benefits tailored to our region’s challenges. Here’s a closer look at where VIG shines, the best frame materials to pair it with, and why expert installation is key to its success.

Best Applications for VIG

VIG excels in areas of your home that face the harshest conditions. For instance, west-facing windows that endure the blazing afternoon sun or south-facing windows with prolonged exposure benefit greatly from VIG’s advanced insulation. These windows are especially valuable in spaces like bonus rooms, upstairs offices, or bedrooms where heat buildup can become unbearable. Additionally, large picture windows or multi-slide patio doors in living and dining areas take advantage of VIG’s slim 5/16-inch profile, offering both insulation and a sleek aesthetic.

If your home is near busy streets, schools, or active neighborhoods, VIG’s sound-dampening qualities can make a noticeable difference. The vacuum layer not only blocks heat but also reduces noise more effectively than standard double-pane glass. Homeowners dealing with persistent drafts, cold spots near windows, or unusually high cooling bills – even with solid insulation and a modern HVAC system – can find relief by combining VIG with advanced low-E coatings.

While choosing the right locations for VIG is important, pairing it with the right frame materials ensures you get the most out of its performance.

Pairing VIG with Window Frame Materials

The beauty of VIG is that it integrates smoothly with modern frame materials, often without requiring major structural changes. Here’s how it works with popular options:

- Vinyl frames: Known for their low thermal conductivity and excellent air sealing, vinyl is a practical and cost-effective choice for retrofitting the 20–35-year-old homes commonly found in Plano, Frisco, and McKinney.

- Fiberglass frames: With their structural strength and minimal thermal expansion, fiberglass frames are ideal for supporting larger VIG units, such as expansive windows or patio doors.

- Aluminum-clad frames: These frames offer a durable and stylish option when designed with thermal breaks to prevent heat transfer.

Each material brings unique advantages, but proper installation is what ensures these benefits translate into real-world results.

The Importance of FGIA-Certified Installation

Even the most advanced VIG unit will underperform if it’s not installed correctly. Achieving airtight, stable integration with the frame and surrounding wall is critical. FGIA-certified installation practices – like precise flashing, shimming, sealing, and secure fastener placement – are designed to prevent water and air infiltration. Without these steps, you risk drafts, leaks, and diminished energy efficiency.

VIG installation also requires careful handling. Over-tightening or improper assembly can place stress on the glass, potentially compromising its long-term durability. FGIA standards address these challenges by accounting for movement between the frame and the structure, which helps preserve the vacuum seal for decades.

At Optimal Windows, we follow these rigorous guidelines to eliminate the common issues found in older North Texas homes, such as drafts, leaks, and builder-grade failures. With proper installation, your VIG windows will deliver the energy savings, comfort, and durability you expect for years to come.

Conclusion

Vacuum Insulated Glass (VIG) represents one of the most advanced residential glazing technologies available today. By using a near-vacuum layer to dramatically reduce heat transfer, VIG delivers elite thermal performance in a slim 5/16-inch profile, rivaling many triple-pane systems without the bulk.

For homeowners in Plano, Frisco, McKinney, and North Dallas, these benefits translate into reduced heat gain, fewer drafts, quieter interiors, and lower HVAC demand during extreme Texas weather.

However, VIG’s performance depends heavily on proper installation. Standards-based installation practices are critical to ensuring durability, efficiency, and long-term value.

At Optimal Windows, we specialize in replacing builder-grade windows in 20–35-year-old North Texas homes using precise, certified installation methods. If you are considering VIG, a professional in-home evaluation can determine whether it is the right solution for your comfort, efficiency, and long-term goals.

FAQs

What’s the difference between vacuum insulated glass and triple-pane windows?

Vacuum insulated glass (VIG) takes energy efficiency to the next level by incorporating a near-vacuum layer between two glass panes. This design significantly reduces heat transfer, offering top-notch insulation without the bulk. What sets VIG apart is its slim, lightweight profile, making it an appealing alternative to traditional triple-pane windows.

Triple-pane windows, on the other hand, achieve insulation through three layers of glass filled with insulating gases like argon or krypton. While effective, these windows are noticeably thicker and heavier. For North Texas homeowners, where managing extreme heat and energy costs is a priority, VIG provides a sleek yet highly efficient option to enhance comfort and minimize heat loss.

What challenges come with installing vacuum insulated glass?

Installing vacuum insulated glass demands extreme attention to detail, particularly when it comes to achieving a perfect seal. This seal preserves the vacuum layer, which is the core of the glass’s energy-saving capabilities. Even a small mistake, like a crack or a compromised seal during installation, can undermine its performance and shorten its lifespan.

Another critical factor is maintaining the vacuum over time. Even tiny leaks can gradually diminish the glass’s insulating effectiveness, making proper installation vital. To ensure the glass performs as it should, it’s essential to rely on skilled professionals with experience in handling and installing this specialized material. Their expertise can help prevent these potential pitfalls and protect your investment.

Does vacuum insulated glass help reduce noise in busy areas?

Vacuum insulated glass is an excellent option for reducing noise, especially in bustling urban settings or near busy streets. Its unique design incorporates a vacuum layer sandwiched between two panes of glass. This vacuum acts as a barrier, significantly cutting down on sound transmission when compared to standard windows. For homeowners seeking a quieter and more peaceful living space, this advanced glass technology offers a practical and effective solution.