Hard Coat vs. Soft Coat Low-E Glass

In North Texas, where summers hit 100°F+ and UV rays are relentless, choosing the right Low-E glass can make or break your home’s energy efficiency and comfort. Builder-grade aluminum windows, common in homes built from 1990 to 2005, often fail to insulate properly, leading to higher energy bills, faded furniture, and overworked air conditioners. Upgrading to Low-E glass – either hard coat or soft coat – can help, but understanding the differences is key.

- Hard Coat Low-E: Durable and scratch-resistant, ideal for colder climates where retaining heat is important. However, it allows more solar heat inside, making it less suitable for Texas summers.

- Soft Coat Low-E: Offers better thermal insulation, significantly reduces solar heat gain (lower SHGC), and reduces UV exposure by approximately 70%–75%, depending on the glass package. It’s the preferred choice for Texas homes, especially for west- and south-facing windows.

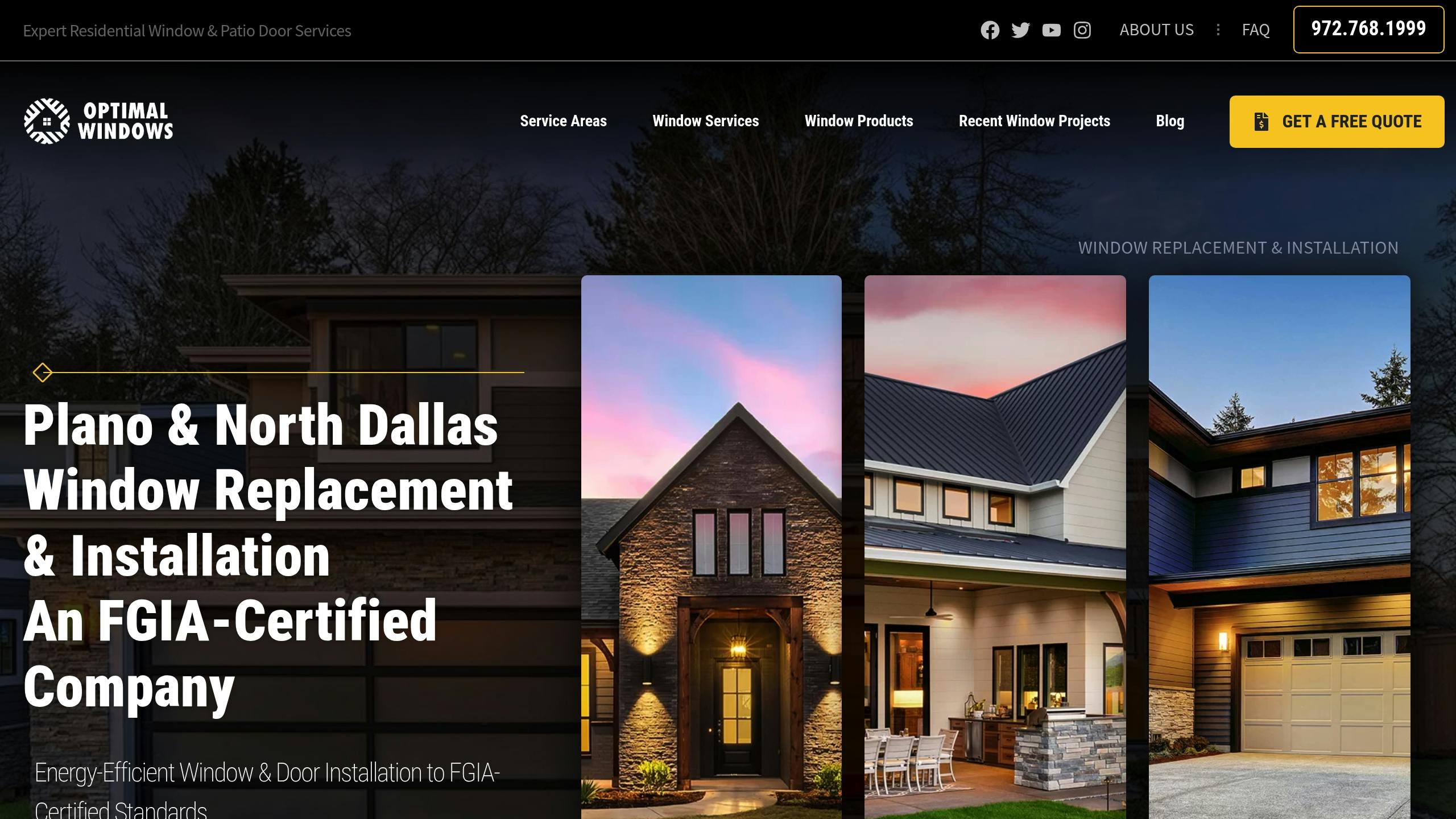

Proper installation is critical. Even the best Low-E glass won’t perform without FGIA-certified installation to prevent leaks, drafts, and early seal failure. For North Texas homeowners, replacing outdated windows with soft coat Low-E glass can significantly reduce window-related energy loss, improve comfort, and help protect interiors from sun damage.

Keep reading to learn how these options compare and why soft coat Low-E glass, paired with expert installation, is the best fit for Texas homes.

Low-E Glass Coating Basics: Hard Coat vs. Soft Coat

How Hard Coat and Soft Coat Are Made

The way Low‑E coatings are made plays a huge role in how they perform. Hard coat Low‑E, also called pyrolytic coating, is created during the float glass manufacturing process while the glass is still molten. At this stage, a thin layer of tin oxide is applied to the molten glass, bonding with it as it cools. According to Jameson Simpson, this method produces a bond that is both durable and scratch-resistant, making it ideal for single-pane applications [7].

On the other hand, soft coat Low‑E follows a completely different process. In this case, pre-cut glass enters a vacuum chamber where 2–3 ultra-thin layers of silver and metal oxides are applied using charged inert gas [6][8]. Daniel Snow, Vice President of Operations at Glass.com, explains:

The vacuum then sputters the metal onto the glass, creating a soft layer [6].

While soft coat Low‑E coatings deliver excellent thermal performance, their delicate silver layers require protection within an insulated glass unit (IGU) to function properly [3][7].

The key difference lies in the materials used: hard coat relies on tin oxide, while soft coat incorporates silver layers that are about 500 times thinner than a human hair [10]. These manufacturing differences directly impact how each type of coating performs in terms of insulation, solar heat control, and durability.

Key Performance Metrics Explained

To understand how hard coat and soft coat Low‑E coatings compare, let’s break it down into four key performance metrics:

- U-Value: This measures a window’s ability to insulate. A lower U-value means better insulation. Regular uncoated glass has an emissivity of 0.84, meaning it easily absorbs and radiates heat. Hard coat Low‑E reduces emissivity to around 0.15, while soft coat achieves an even lower emissivity of approximately 0.10, providing superior insulation [2]. When paired with double-pane construction, Low‑E coatings can bring U-factors down to as low as 0.20 to 0.30 [9].

- Solar Heat Gain Coefficient (SHGC): This metric reflects how much solar heat enters through the glass. In hot climates like Texas, a lower SHGC is crucial to keep indoor temperatures comfortable. Hard coat allows more solar heat to pass through, which can be beneficial in colder regions for passive heating [7][4]. However, soft coat excels at blocking solar heat, resulting in a lower SHGC, making it the better choice for homes in North Texas [4].

- Visible Light Transmittance (VLT): VLT measures how much natural daylight enters your home. Higher percentages mean brighter interiors. Many modern Low-E coatings are designed to maintain high visible light transmission while improving energy efficiency, with exact VLT varying by coating type and configuration [9]. Soft coat Low‑E generally provides clearer optics with reduced haze compared to hard coat [3].

Each type of coating has its strengths. Hard coat is highly durable and scratch-resistant, making it suitable for exposed use. Soft coat, while offering better thermal performance and optical clarity, must be sealed within an IGU to protect its delicate layers [7][3]. These differences make soft coat the preferred option for energy-conscious homeowners in North Texas.

Hard Coat Low-E Glass: Features and Applications

Durability and Scratch Resistance

Hard coat Low-E glass stands out for its toughness, thanks to a unique manufacturing process. During production, a thin layer of tin oxide is applied to the glass while it’s still molten or extremely hot. This process, known as pyrolytic coating, creates a strong, permanent bond between the coating and the glass. As Lauren Chorzempa from Heartland Glass explains:

“This process [pyrolytic] welds the coating to the glass, making it harder to scratch.” [11]

The result is a microscopically thin coating that is permanently bonded to the glass surface, making it nearly invisible while remaining highly durable. Because hard coat Low-E is fused to the glass during manufacturing, it can withstand cleaning, handling, and exposure without special fabrication requirements. This durability makes it a practical choice for applications where the coating may remain exposed, such as storm windows or certain retrofit situations.

Performance Limits in Hot Climates

While hard coat Low-E glass is built to last, its thermal performance can be a drawback in hot climates like North Texas. With a higher Solar Heat Gain Coefficient (SHGC), it allows more solar energy to pass through [3]. Its emissivity value, typically around 0.15, is higher than the 0.10 commonly seen in soft coat Low-E glass [2]. This means more infrared and ultraviolet light enters the home, potentially increasing cooling costs during the scorching Texas summers. Penn State University notes:

“Hard coat is not quite as energy efficient as soft coat, but is tough enough to be used on surfaces exposed to the elements.” [2]

Additionally, hard coat glass can appear hazier, with a less clear and vibrant appearance compared to soft coat options [3]. This aesthetic difference may also factor into its suitability for certain projects.

When Hard Coat Makes Sense

Despite its limitations in managing heat, hard coat Low-E glass has clear advantages for specific situations. Its weather resistance makes it a reliable choice for storm windows or retrofit projects, where an extra layer of protection is added to existing windows [2]. It’s also a smart option for windows with integrated features, like blinds installed between the panes, as the durable coating can handle the added wear [3].

For cost-conscious homeowners, hard coat Low-E glass offers a more affordable alternative to soft coat options. However, its higher SHGC often makes it less ideal for primary windows in homes exposed to intense sunlight, like those in North Texas. In such cases, the slightly higher upfront cost of soft coat Low-E glass – typically 10% to 15% more than standard glass [12] – is often offset by long-term energy savings, making it a better choice for the region’s climate challenges.

Soft Coat Low-E Glass: Features and Applications

Superior Energy Efficiency and Solar Control

When it comes to energy efficiency and solar control, soft coat Low-E glass stands out as a top choice for homes in North Texas. This advanced glass is manufactured using a sputtering process, where 2–3 ultra-thin layers of silver are applied in a vacuum chamber. The result? A high-performance solar control glass that reflects solar heat instead of absorbing it, making it especially effective for Texas’s hot climate [1][3][4].

For homeowners dealing with scorching summers, soft coat Low-E coatings can meaningfully reduce solar heat gain and cooling demand, contributing to lower energy use in hot climates. Experts highlight its dual functionality:

“The soft coat offers superior UV protection when compared to the cold-weather option. It also reflects both warm and cold air back into a room instead of allowing leakage.” [1]

This glass doesn’t just block heat; it also reduces UV transmission by 70% to 75%, shielding your furniture, flooring, and artwork from fading. Since the coating is delicate, it’s sealed within an insulated glass unit (IGU) to prevent oxidation and physical damage [1][3]. For North Texas homes, these features translate to lower energy costs and a more comfortable living environment year-round.

Better Clarity and Appearance

Energy efficiency aside, soft coat Low-E glass also excels in visual performance. Unlike hard coat options, which can sometimes appear slightly hazy, soft coat glass offers exceptional clarity and a neutral, nearly invisible finish [3]. As Energy Window Solutions explains:

“Modern coatings are so advanced that they’re nearly invisible, allowing for ample sunlight without sacrificing the benefits of temperature control and protection.” [13]

Soft coat Low-E glass maintains 70%-80% visible light transmission, ensuring your home is filled with natural light while significantly reducing glare. This balance creates what Texas Made Windows describes as an “‘invisible’ window shade that offers full transparency” [1]. For homeowners who value aesthetics as much as energy savings, this glass provides the best of both worlds.

Where Soft Coat Works Best in North Texas

In North Texas cities like Plano, Frisco, McKinney, and North Dallas, soft coat Low-E glass is particularly effective for west- and south-facing windows that bear the brunt of the intense afternoon sun. These windows often face what locals call the “afternoon bite”, when temperatures soar and air conditioning systems are pushed to their limits. Soft coat Low-E glass helps to mitigate this strain, keeping homes cooler and more comfortable.

For even greater performance, pairing soft coat Low-E glass with modern vinyl or fiberglass frames creates a strong barrier against North Texas’s extreme weather swings. Adding argon or krypton gas fills between the panes further enhances insulation. While soft coat units typically cost 10% to 15% more than standard double-pane windows, the energy savings they provide often offset this cost within 3 to 5 years [9]. Replacing builder-grade aluminum windows with soft coat Low-E glass in sealed IGUs not only improves comfort immediately but also delivers ongoing savings and durability over time.

Hard Coat vs. Soft Coat: Which Is Right for Your Home?

Performance and Durability Differences

When it comes to Low-E glass, hard coat and soft coat options each serve distinct purposes. Knowing their differences can help you make the right choice for your home. Hard coat Low-E is fused directly to the glass during manufacturing, making it durable and tough. On the other hand, soft coat Low-E is applied in multiple layers within a sealed insulated glass unit (IGU), which significantly boosts its thermal performance.

Soft coat Low-E stands out for its energy efficiency. It lowers U-values and reduces solar heat gain, which translates into noticeable cooling cost savings – especially in the scorching Texas heat [5, 9]. Additionally, soft coat glass offers superior optical clarity with a neutral, nearly invisible finish. In contrast, hard coat glass can sometimes appear slightly hazy or have a faint tint [5, 16]. When it comes to UV protection, soft coat glass blocks 70%–75% of harmful UV rays, outperforming the moderate UV-blocking capabilities of hard coat glass [5, 11].

Climate and Sun Exposure Factors

In North Texas, where cooling is a top priority, soft coat Low-E glass is specifically designed to handle the challenges of a hot, sun-drenched environment [15, 16]. Hard coat glass, with its higher Solar Heat Gain Coefficient (SHGC), allows more solar heat to pass through, making it better suited for colder climates where passive solar heating is beneficial. However, this feature can work against you during the sweltering Texas summers [5, 9].

The orientation of your windows also plays a critical role. South- and west-facing windows, which endure the brunt of the afternoon sun, benefit most from high-performance soft coat options like Cardinal Low-E 340 or 366 [7, 16]. These coatings are typically applied to the #2 surface (the inner side of the outer pane) to reflect solar heat before it enters your home [7]. For homeowners in the Dallas area, choosing the right Low-E coating can lead to energy savings of up to 30% on heating and cooling bills [13]. Hard coat glass is better suited for specific uses, such as storm doors or single-pane glass where the coating is exposed [6, 9].

By factoring in climate and sun exposure, you can select the coating that delivers long-term comfort and energy savings tailored to your home.

How Optimal Windows Selects the Right Coating

At Optimal Windows, we take these performance differences into account to recommend the best solution for your home. Our team carefully evaluates your home’s orientation, sun exposure, and comfort needs to determine which Cardinal Low-E coating is the right fit. For most homes in Plano, Frisco, McKinney, and North Dallas, soft coat options like Cardinal LoĒ-366 strike a great balance between energy efficiency and comfort. Homes with intense west or south-facing exposures often benefit from the advanced solar control provided by Cardinal LoĒ-340 [14].

Our FGIA-certified installation process ensures that your IGU is sealed and aligned properly, preventing air leaks that could affect the coating’s performance [13]. For homeowners wanting the best year-round insulation, we can combine soft coat solar control with Cardinal i89 Interior Low-E, applied to the #3 surface. This dual-coating system reflects heat outward during summer and inward during winter, delivering some of the lowest U-values available. Plus, it maintains excellent optical clarity and helps reduce interior condensation.

Optimal Windows: FGIA-Certified Installation for North Texas Homes

Why Certified Installation Matters

When it comes to energy efficiency, even the most advanced window glass can’t work its magic without proper installation. FGIA-certified installation ensures that your windows are aligned and sealed correctly, eliminating air leaks that can undermine insulation. This process is especially critical for soft-coat Low-E glass, which features delicate silver layers that require careful handling. As Energy Window Solutions emphasizes:

“For Low-E coatings to perform at their best, professional window installation is essential. Proper installation ensures that the coatings are aligned and sealed correctly, preventing air leaks that could compromise the insulation benefits.” [13]

Our certified installers go the extra mile to protect the hermetic seal of your insulated glass unit (IGU). This attention to detail prevents seal failures that often lead to fogging or deterioration of the coatings. With proper manufacturing and FGIA-certified installation, Low-E coatings are protected within the IGU and designed to maintain stable performance over the service life of the insulating glass unit. [9][13].

Cardinal Glass Options for Every Home

To meet the diverse needs of North Texas homeowners, we offer the full range of Cardinal LoĒ glass options. Each product is designed to address specific sun exposure challenges and enhance comfort:

- Cardinal LoĒ-366: A well-rounded choice for energy efficiency, ideal for most homes in the area.

- Cardinal LoĒ-340: Perfect for homes with west- or south-facing windows, offering exceptional solar control and a low solar heat gain coefficient.

- Quad LoĒ-452+: With four layers of silver, this option provides unmatched performance for extreme heat conditions.

- Cardinal i89: An interior Low-E coating that reflects heat back into your home, making it particularly useful during winter months [5].

Standard soft-coat Low-E glass typically blocks approximately 70%–75% of harmful UV rays, while premium solar-control coatings such as Cardinal LoĒ-452 can block up to approximately 95%–97% of UV radiation, depending on the insulated glass configuration. For added efficiency, argon gas fill can improve insulating performance compared to air-filled units, with the exact benefit depending on IGU design and fill rate. [9]. Together, these features provide measurable savings on cooling costs during Texas’s sweltering summers, while also upgrading your home’s overall window performance.

Replacing Builder-Grade Aluminum Windows in North Dallas

Many homes in Plano, Frisco, McKinney, and North Dallas still rely on builder-grade aluminum windows, which are notorious for conducting heat quickly and offering minimal insulation. No matter how advanced the glass, these frames simply can’t keep up with modern energy standards [15]. That’s why we specialize in replacing these outdated units with frames made from vinyl, fiberglass, or composite materials. These modern alternatives offer significantly better thermal resistance and help keep your home comfortable year-round.

Our replacement process doesn’t just stop at upgrading the frames. We address common issues found in builder-grade installations, such as drafts, leaks, and poor sealing around brick and siding. Paired with high-performance soft-coat Low-E glass designed for Texas’s extreme heat, this upgrade can lower cooling costs by 25% to 40% [9]. In fact, the energy savings often offset the cost of the replacement within just 3 to 5 years [9]. Beyond the numbers, this transformation enhances the comfort and efficiency of your entire home.

Different Types of Low-E Glass (You Need To Know Before Buying Windows)

Conclusion

Choosing the right Low-E glass for your home means considering both the unique demands of North Texas’s climate and your specific needs. While hard coat Low-E glass is known for its durability and scratch resistance, it’s better suited for colder regions where capturing heat from the sun is beneficial. For homes in Plano, Frisco, McKinney, and North Dallas, soft coat Low-E glass stands out for its superior energy efficiency and UV protection, blocking up to 70% more UV rays compared to standard glass [3][16]. This not only helps reduce cooling costs but also shields your furniture and flooring from sun damage. However, even the best glass won’t deliver its full benefits without proper installation.

At Optimal Windows, we pair Cardinal LoĒ glass options with FGIA-certified installation expertise to ensure your windows perform at their best. Our team is trained to handle delicate soft-coat layers with care, maintain precise seals, and address the common issues found in older builder-grade windows throughout North Dallas suburbs.

Whether you’re upgrading to energy-efficient glass or replacing outdated windows, combining the right Low-E coating with expert installation ensures long-term comfort and noticeable savings. For North Texas homeowners, this means enjoying cooler summers, protecting your interiors, and seeing the difference in your energy bills.

FAQs

What’s the difference between hard coat and soft coat Low-E glass?

Soft coat Low-E glass and hard coat Low-E glass may sound similar, but they serve different purposes and excel in specific situations. Let’s break it down to help you understand which option might work best for your home.

Hard coat Low-E glass is created by applying a thin metallic layer directly onto the glass during production. This process results in a tough, durable surface that holds up well in single-pane windows or storm doors. It’s also a more budget-friendly option. However, hard coat glass doesn’t block heat and UV rays as effectively, which means it falls short when it comes to energy efficiency. In Texas, where the summer sun can be relentless, this could lead to higher energy bills and less indoor comfort.

Soft coat Low-E glass, on the other hand, takes energy efficiency to the next level. This type of glass features multiple ultra-thin layers of metal that are applied after the glass is formed. These coatings are designed to reflect heat and block UV rays, all while maintaining excellent clarity. While soft coat glass is more delicate and must be sealed within insulated glass units (IGUs), it’s the go-to choice for double-pane windows in homes aiming for better energy performance.

For homeowners in Plano, Frisco, McKinney, Allen, and North Dallas, soft coat Low-E glass is often the smarter choice. It’s designed to handle the extreme heat and UV exposure common in Texas, offering improved indoor comfort, lower energy costs, and durability that stands the test of time.

Why is soft coat Low-E glass ideal for homes in North Texas?

Soft coat Low-E glass is particularly well-suited for homes in North Texas, where the intense heat and abundant sunshine demand effective solutions to manage indoor temperatures. This type of glass is designed to block 65–95% of infrared and UV rays, far exceeding the 45–70% typically managed by hard coat glass. By significantly reducing heat transfer, it helps maintain cooler indoor spaces and can lead to noticeable savings on air conditioning during the region’s long, sweltering summers.

Beyond its ability to enhance energy efficiency, soft coat Low-E glass also provides improved optical clarity. It filters out harmful UV rays that contribute to the fading of furniture and flooring, all while allowing natural light to fill your home. Specifically crafted for warmer climates, this glass reflects heat outward while keeping interiors bright and inviting. When installed by FGIA-certified professionals, such as the team at Optimal Windows, soft coat Low-E glass combines performance, durability, and comfort – perfectly tailored for the demands of North Texas living.

Why is proper installation important for Low-E glass windows?

Proper installation plays a key role in ensuring Low-E glass windows deliver the energy savings and comfort they’re designed to provide. When done correctly, the soft-coat layer – an essential component of Low-E glass – is safely sealed within the insulated glass unit (IGU). This protects it from scratches and moisture, which could otherwise damage its heat-reflective properties. On the other hand, poor installation, such as misaligned panes or improper sealing, can lead to increased heat transfer and reduced efficiency.

The placement of the Low-E coating is equally important. In warmer climates like Texas, the coating is typically applied to the inner surface of the outer pane to reflect heat effectively. In colder regions, it’s positioned on the outer surface of the inner pane to help retain heat. Installing the coating on the wrong surface can disrupt the window’s ability to regulate temperature and diminish its energy-saving benefits.

For homeowners in North Dallas, Plano, Frisco, McKinney, and Allen, Optimal Windows ensures installations meet FGIA-certified standards. This meticulous approach prevents drafts, leaks, and noise while maintaining the performance and durability of Low-E glass windows. It’s a crucial step for achieving long-term energy efficiency and comfort, especially in older homes.