Why Builder-Grade Windows Fail in Texas Heat

If your home in Plano or Frisco was built between 1990 and 2005, there’s a strong chance your windows are reaching the end of their useful life. Many homes from this era were equipped with builder-grade aluminum or early vinyl windows that were never designed to withstand decades of North Texas heat and UV exposure.

Over time, these conditions lead to common issues such as rising cooling bills, uneven indoor temperatures, fogging between glass panes, and warped or difficult-to-operate frames.

This article explains why builder-grade windows fail in Texas climates, the specific challenges they face, and how modern replacement windows are engineered to perform better. Whether you’re noticing drafts, higher energy costs, or simply want a clearer understanding of your options, this guide will help you make an informed decision about upgrading your windows.

How Texas Heat Damages Builder-Grade Windows

Texas heat accelerates window failure because builder-grade systems were never engineered for prolonged exposure to extreme temperatures, intense UV radiation, and daily thermal cycling. In North Texas, window frames and glass are subjected to constant expansion during the day and contraction at night, placing repeated stress on seals, spacers, and frame materials. Over time, this movement weakens insulated glass seals, allows argon gas to escape, and creates pathways for air and moisture intrusion. UV exposure further breaks down lower-quality vinyl and plastic components, making frames brittle, warped, or difficult to operate. These combined stresses explain why builder-grade windows often begin to fail long before their advertised lifespan in Plano and Frisco homes.

Frame Warping and Cracking in Aluminum and Early Vinyl

Builder-grade aluminum and early vinyl frames fail in Texas heat because they lack the structural engineering needed to manage extreme temperature swings. Aluminum frames without a thermal break rapidly absorb exterior heat and transfer it directly indoors. As temperatures rise, the metal expands faster than the surrounding glass and seal materials, creating stress at the corners and along the insulated glass edge. Over time, this movement leads to air leaks, broken seals, and reduced structural integrity.

Early-generation vinyl frames present a different problem. Vinyl expands and contracts at a much higher rate than glass, and in prolonged North Texas heat, lower-grade vinyl can soften, bow, or twist out of square. This is especially common on south- and west-facing windows and darker frame colors, where surface temperatures are highest. Once a vinyl frame distorts, sash alignment suffers, locks no longer seal properly, and the insulated glass unit is placed under constant stress — accelerating fogging, seal failure, and operational issues.

Without the protection of high-quality UV stabilizers, vinyl deteriorates further, leading to cracks and operational problems.

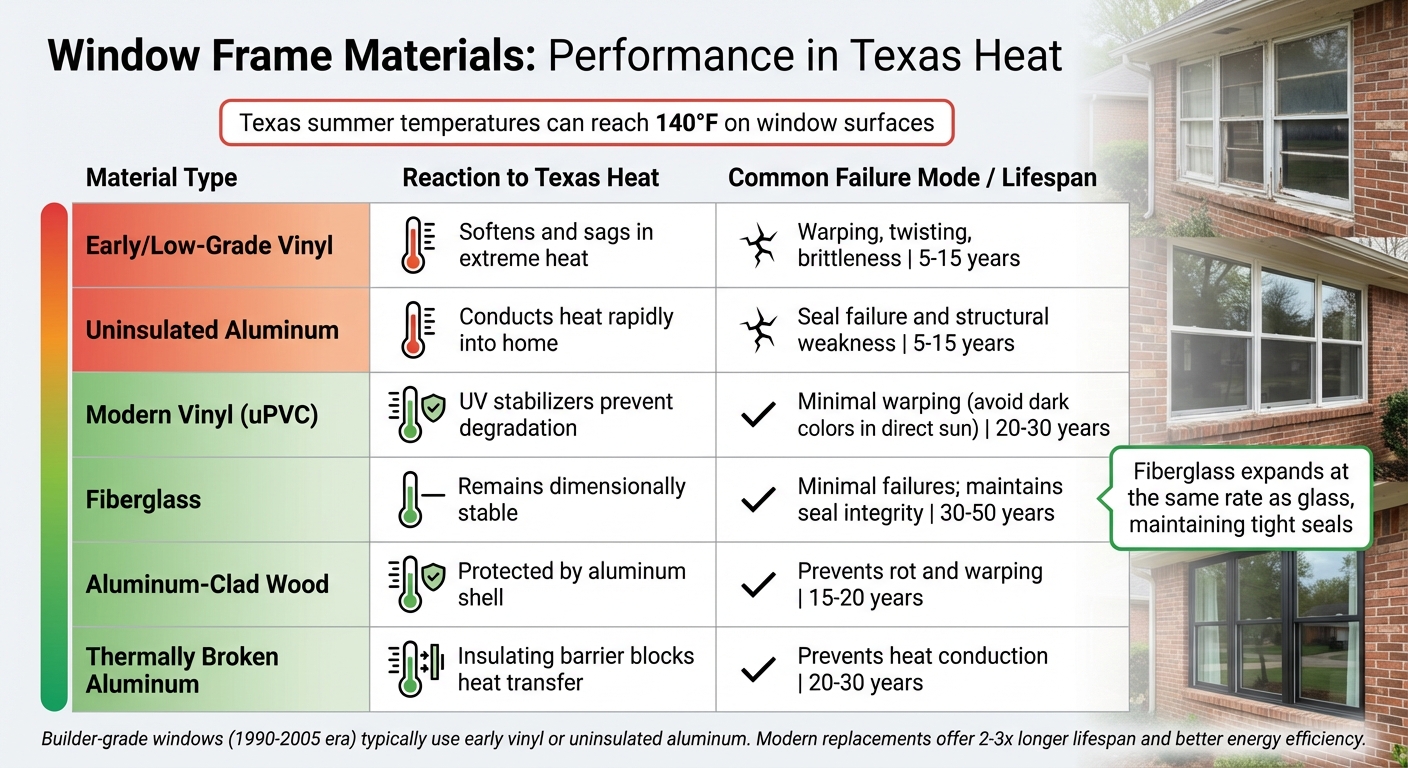

| Material | Reaction to Texas Heat | Common Failure Mode |

|---|---|---|

| Early/Low-Grade Vinyl | Softens and sags | Warping, twisting, and brittleness |

| Uninsulated Aluminum | Conducts heat rapidly | Seal failure and structural weakness |

| Fiberglass | Remains dimensionally stable | Minimal; maintains seal integrity |

Seal Failure in Double-Pane Glass Units

In Texas heat, builder-grade insulated glass units fail because repeated expansion and contraction places constant stress on the edge seals. As outdoor temperatures climb, the glass and frame expand at different rates, creating a pumping effect that slowly weakens the seal holding the panes together. Older builder-grade windows commonly used lower-grade seal systems that lose elasticity over time, making them unable to maintain an airtight bond under prolonged thermal stress..

High heat exacerbates this problem. At temperatures of 140°F, sealants can become six to eight times more permeable than they are at 68°F, allowing insulating gases like argon to escape and letting moisture-laden air seep in. Research published in the MDPI Buildings Journal highlights this issue:

Both temperature and pressure fluctuations lead to mechanical stress on the edge seal which can affect elasticity and accelerate physical deterioration.

When this happens, fogging or condensation often appears between the panes, signaling that the insulated glass unit has lost its ability to effectively regulate temperature.

Energy Loss and Higher Cooling Costs

When seals fail and window frames start to break down, the flaws we’ve already touched on lead to noticeable energy loss. According to Energy.gov, “heat gain and loss through windows are responsible for 25%–30% of residential heating and cooling energy use”. For homeowners in North Texas, where air conditioning runs for most of the year, these inefficiencies can quickly translate into high utility bills and uncomfortable indoor temperatures.

Outdated Glass Technology and Heat Transfer

The problem doesn’t stop with seals and frames – outdated glass technology makes energy inefficiency even worse. Many builder-grade windows, common in Plano and Frisco homes built between 1990 and 2005, lack modern spectrally selective Low-E coatings. Without these coatings, up to 40% to 70% more solar heat enters the home compared to homes with today’s advanced treated glass. This extra heat buildup forces HVAC systems to work harder, especially in rooms with west- and south-facing windows.

Older double-pane windows with high SHGC (Solar Heat Gain Coefficient) values and uninsulated aluminum frames also contribute to rising indoor temperatures. These outdated designs allow solar heat and outdoor temperatures to significantly affect indoor comfort.On the other hand, modern windows with Low-E coatings can cut energy loss by 30% to 50% compared to standard windows. High-performance glass, such as Cardinal LoĒ-340, is particularly effective – it blocks 82% of solar heat while still letting in 40% of natural light.

In North Texas, where summers are intense and long, inefficient windows lead to warmer interiors, more frequent air conditioning cycles, and increased energy costs. Upgrading to modern replacement windows designed for extreme heat can make a noticeable difference in comfort and energy savings.

How Modern Replacement Windows Perform Better in Texas Heat

Modern replacement windows are specifically designed to handle the challenges of Texas weather, where extreme heat and intense sunlight can push older windows to their limits. The key lies in improved materials and advanced glass technology that are built to perform under these conditions.

Older builder-grade aluminum frames, common in many homes, tend to conduct heat directly into your living space. In contrast, today’s replacement windows use materials that act as insulators, reducing heat transfer. Options like fiberglass, modern vinyl, and aluminum-clad wood are crafted to endure decades of intense Texas sun without warping, cracking, or losing their seals. These frames are paired with glass coatings that block solar heat while still allowing natural light to brighten your home.

This combination ensures better structural integrity, energy efficiency, and comfort – especially during those sweltering summer months. Below, we’ll explore how these materials and advanced glass technologies deliver long-lasting performance.

Frame Materials and Advanced Glass Options

Fiberglass is one of the most durable and heat-resistant materials available for window frames. Its ability to expand and contract at nearly the same rate as the glass it holds ensures that seals remain tight over time. This stability helps fiberglass frames last 30 to 40 years, all while reducing heating and cooling costs by 20% to 40%. Fiberglass is especially well-suited for North Texas, where temperature swings can cause other materials to loosen or allow moisture to seep in. It’s also a great option for homeowners who prefer dark-colored frames, such as black or charcoal, as fiberglass resists warping even with darker finishes.

Modern vinyl (uPVC) has come a long way from the brittle, builder-grade vinyl used in older homes. Today’s vinyl frames are fortified with UV stabilizers, which prevent cracking and brittleness caused by prolonged sun exposure. While vinyl is a more budget-friendly option compared to fiberglass, it’s worth noting that dark-colored vinyl frames may still warp or fade when exposed to intense sunlight. When properly manufactured, vinyl frames typically last 20 to 30 years and are a solid choice for North Texas homes.

Aluminum-clad wood offers the beauty of a wood interior with the durability of an extruded aluminum exterior. The aluminum shell protects the wood core from UV rays, heat, and moisture, preventing the rot and warping often seen in traditional wood frames. For homeowners who want the classic look of wood without the maintenance, this is an excellent choice. With proper care, these frames typically last 15 to 20 years.

Thermally broken aluminum is a major improvement over standard builder-grade aluminum frames. It includes an insulating barrier, known as a “thermal break”, which prevents the metal from conducting outside heat into your home. When choosing aluminum frames, it’s crucial to ensure they are thermally broken to avoid turning your window frames into heat conductors.

On the glass front, modern replacement windows incorporate spectrally selective Low-E coatings that are tailored to specific sun exposures. For example, Cardinal LoĒ-366 is a versatile option that blocks 95% of harmful UV rays, offering balanced heat rejection. For west-facing windows that endure the harshest afternoon sun, Cardinal LoĒ-340 is a better choice, as it blocks 82% of solar heat with a Solar Heat Gain Coefficient (SHGC) of just 0.18. When having larger windows or sliding doors, Cardinal Quad LoĒ-452⁺ uses multiple metallic oxide layers to filter infrared radiation while maintaining natural brightness.

Why FGIA-Certified Installation Matters

Modern replacement windows come with advanced materials and cutting-edge glass technology, but their performance over time heavily depends on how well they’re installed. Even the highest-quality windows can fall short in Texas’s extreme climate if they aren’t installed correctly. FGIA-certified installation (formerly known as AAMA) adheres to rigorous industry standards, such as AAMA 2400 and FMA/AAMA 100, which outline precise methods for sealing, flashing, and supporting windows to handle harsh weather conditions effectively. These standards are critical to ensuring your windows perform as intended for decades, rather than developing leaks or fogging just a few years down the line. In North Texas, certified installation is often the difference between a window lasting 10 years versus 30.

Opting for certified full-frame replacement, rather than simply replacing the sash, is essential for long-term durability. This comprehensive approach addresses flashing, insulation, and water management around the entire window opening. In North Texas, where builder-grade installations often skipped proper flashing or relied on inexpensive organic felt that deteriorates quickly in humid conditions, this step is especially important. Certified installers use high-quality synthetic weather barriers that maintain a tight seal for years to come. Additionally, they ensure lintels are properly positioned to distribute the home’s structural load away from the window frame, preventing warping or cracking. Certified techniques also safeguard the insulating glass units (IGUs), helping them retain argon gas with a minimal loss rate of less than 1% per year. These careful practices not only enhance energy efficiency but also ensure the windows’ lasting performance.

Improper installation can lead to significant energy losses, potentially adding up to $300 annually in heating and cooling costs due to air leaks. Certified installation guarantees that windows meet specific Performance Grade (PG) and Design Pressure (DP) ratings, ensuring they can withstand air and water infiltration during intense Texas storms. When you invest in new replacement windows, choosing a certified installation is the best way to achieve the energy savings, comfort, and durability you’re looking for.

Benefits of Replacing Builder-Grade Windows in North Texas

Upgrading outdated windows doesn’t just address energy inefficiencies and maintenance headaches – it also improves your home’s overall functionality and comfort.

Lower Energy Costs and Enhanced Durability

Switching from builder-grade windows to modern Low-E glass options can significantly reduce energy loss, cutting it by 30–50%. This upgrade translates to annual savings of $101–$583 on energy bills, and ENERGY STAR-certified models can lower costs by up to 13%.

Beyond energy savings, high-quality materials like fiberglass offer remarkable durability, lasting 30–50 years compared to the 5–15 years typical of older aluminum or basic vinyl windows. This means fewer replacements and less hassle with issues like fogged glass, broken seals, or warped frames. Advanced materials are designed to withstand North Texas’ intense heat without warping or cracking, ensuring airtight seals remain intact for decades.

Replacing windows also eases the strain on your HVAC system. High-performance glass, such as Cardinal LoĒ-340, which blocks 82% of solar heat, helps keep indoor temperatures stable. This reduces the workload on your air conditioner, lowering utility bills and prolonging the life of your cooling equipment.

These practical benefits go hand in hand with noticeable improvements in comfort and aesthetics.

Quieter Interiors and Enhanced Curb Appeal

Modern replacement windows don’t just improve energy efficiency – they also reduce noise and elevate your home’s appearance. Unlike thin, poorly sealed builder-grade aluminum frames, advanced windows with tighter seals, multiple panes, and improved frame materials significantly cut down on outdoor noise. This is especially valuable for homes near busy streets, schools, or other noisy areas. For those looking for even more soundproofing, laminated glass can offer an extra layer of noise reduction.

Visually, new windows can transform your home’s exterior. Sleek designs and modern finishes enhance curb appeal, often boosting property value. In fact, window replacements typically recoup 70–78% of their cost. Additionally, energy-efficient features are highly attractive to over 90% of homebuyers, giving your home an edge in the competitive North Texas real estate market.

Choosing the Right Windows for Your Plano or Frisco Home

When it comes to replacing windows in North Texas, the key is selecting materials that can handle the region’s intense heat and shifting conditions. Durable frame materials paired with advanced glass technology are essential. Fiberglass frames stand out as a top choice for extreme temperatures. They expand and contract at nearly the same rate as glass, which helps maintain seal integrity even during significant temperature changes. This makes fiberglass an excellent option, especially if you’re considering dark-colored frames like black, which tend to absorb more heat. On the other hand, modern vinyl offers a more budget-friendly, insulated alternative. However, darker vinyl frames should be avoided in areas with direct sunlight, as prolonged UV exposure can cause warping or brittleness over time.

When selecting glass, focus on options designed to reduce heat transfer. South and west-facing windows, low-SHGC glass is ideal for minimizing solar heat gain. For example, Cardinal LoĒ-340 glass blocks 82% of solar heat, making it a great choice for windows that face intense afternoon sun. For other orientations, LoĒ-366 balances heat rejection with natural light, providing versatility for different parts of your home. Always check the NFRC label for whole-unit ratings instead of relying solely on center-of-glass numbers. Whole-unit ratings give a more realistic view of how the window will perform once installed. While choosing the right materials is critical, the way your windows are installed is just as important.

Proper installation ensures that even the most advanced windows perform as intended. Look for FGIA-certified installation practices, which emphasize correct sealing and flashing techniques. As Chris Wager from Southwest Exteriors points out:

A great product installed poorly will disappoint fast in Texas weather.

Full-frame replacement is often the best choice, as it addresses potential flashing issues and allows for the use of high-quality synthetic sealants designed to resist North Texas humidity.

Local professionals in Plano and Frisco specialize in upgrading older homes using FGIA-certified installation methods and advanced Cardinal glass products. This combination of durable frames, efficient glass, and expert installation ensures your home stays comfortable and energy-efficient, even during the harshest Texas summers.

FAQs

What are the signs that my builder-grade windows are failing in the Texas heat?

Builder-grade windows often fall short when it comes to handling the harsh Texas climate. The intense heat and relentless UV rays can lead to several noticeable problems. Signs of trouble might include panes fogging up or showing condensation between the glass, drafts sneaking in around the frames, or frames that have warped or cracked over time. You may also find that your windows are harder to open and close, or that certain rooms remain stubbornly warm despite running the air conditioner.

If you’ve noticed rising energy bills or your windows are failing to maintain a comfortable indoor environment, it could be time to explore sturdier, energy-efficient replacement options built to withstand North Texas’s demanding conditions.

What are the advantages of upgrading builder-grade windows in Texas homes?

Builder-grade windows, commonly found in Plano and Frisco homes built during the 1990s and early 2000s, were often constructed with cost-effective materials like thin aluminum frames, one coating Low E double-pane glass, and minimal weatherproofing. While these materials helped builders meet budgets, they weren’t designed to handle the relentless Texas heat and humidity. Over time, this can lead to problems like warped frames, failed seals, drafts, and rising energy costs.

Switching to modern, energy-efficient windows can solve these issues while offering a range of long-term benefits. Options like fiberglass, vinyl, or aluminum-clad wood frames paired with Low-E glass provide better insulation, limit heat transfer, and block harmful UV rays. This not only helps lower cooling costs but also protects furniture and flooring from fading while improving overall indoor comfort. Additionally, modern windows are built to last longer, reduce maintenance needs, and provide better noise reduction – an important feature for homes near busy roads or schools.

When these advanced windows are installed by FGIA-certified professionals, such as the team at Optimal Windows, homeowners can trust that the sealing and insulation will be done correctly. Proper installation ensures the windows perform as intended, offering improved energy efficiency and durability, even in the challenging North Texas climate.

Why is it important to have FGIA-certified installation for windows in Texas?

FGIA-certified installation guarantees that your windows are sealed and insulated correctly, adhering to rigorous industry standards. This level of precision is especially important in Texas, where the relentless heat, powerful sunlight, and high humidity can lead to early window failures if they aren’t installed properly.

By aligning with FGIA guidelines, certified installation minimizes heat gain, UV exposure, and moisture issues, enhancing energy efficiency, indoor comfort, and the overall durability of your windows. It’s a reliable way to safeguard your home and ensure your windows perform their best in Texas’s demanding climate.